Taizy poultry feed pellet making machine grinds and compresses the raw materials to produce compact feed pellets. It has a huge range of applications for processing corn, alfalfa, bran, and grass into different sizes of pellets for feeding various animals (Common diameters are: 2mm, 4mm, 6mm, and 8mm).

Our feed pellet machine can produce 80-700kg of pellets per hour. It is simple to operate, easy to adjust and clean. Our animal feed pellet mills have been exported to India, the U.S., Vietnam, etc. Its excellent performance and quality have brought us many repeat customers.

Animal feed pelleting machine parameters

| Model | Power | Capacity | Weight | Size |

| TZ-120 | 3kw or 170F Gasoline engine | 80-100kg/h | 75kg | 850*350*520mm |

| TZ-150 | 3kw or 170F Gasoline engine | 100-150kg/h | 81kg | 850*350*570mm |

| TZ-210 | 7.5kw or 18HP diesel engine | 200-300kg | 170kg | 990*430*710mm |

| TZ-230 | 11kw or 20HP diesel engine | 300-450kg/h | 250kg | 1000*450*960mm |

| TZ-260 | 15kw or 22HP diesel engine | 400-500kg/h | 290kg | 1300*450*1100mm |

| TZ-300 | 22kw diesel engine | 600-700kg/h | 397kg | 1360*570*1150mm |

We offer a range of machine models, each with various output options. You can select from a wide array of power sources, including electric motors, diesel engines, PTO, and gasoline engines, depending on your specific needs. Typically, larger models are compatible with electric motors and diesel engines.

The feed pellets produced by these machines can be customized to different sizes by using molds with varying diameters. Additionally, this feed pellet mill can produce livestock feed pellets with different compression ratios based on the characteristics of the raw materials used.

Advantages of poultry feed machine

- Easy to operate: the poultry feed pellet making machine adopts the feed processing method of dry-in and dry-out. And there is no need to add liquid additives to it during granulation. Also, the material coming out of the discharge port does not need to be dried. So it is easy to operate and reduce production costs.

- Durable: the template and roller of the machine are made of high-alloy wear-resistant materials, with a reasonable structure and strong wear resistance. At the same time, it adopts the process of extrusion granulation. So it solves the problems that are difficult with traditional feed processing and granulation. And the raw materials need to be crushed and dried.

- Advanced technology: This poultry feed pellet making machine has a bactericidal effect on the granulation process. It can kill the germs and microorganisms mixed in the raw feed materials. At the same time, the excess water is discharged through extrusion, so it can be preserved for a long time.

- Huge range of applications: Livestock feed pellet making machine creates pellet feed for a variety of animals, including chickens, geese, pigeons, rabbits, cows, sheep, cattle, and pigs. And corn, alfalfa, bran, grass, rice, beans, and oil cake can be the raw materials to make feed pellets.

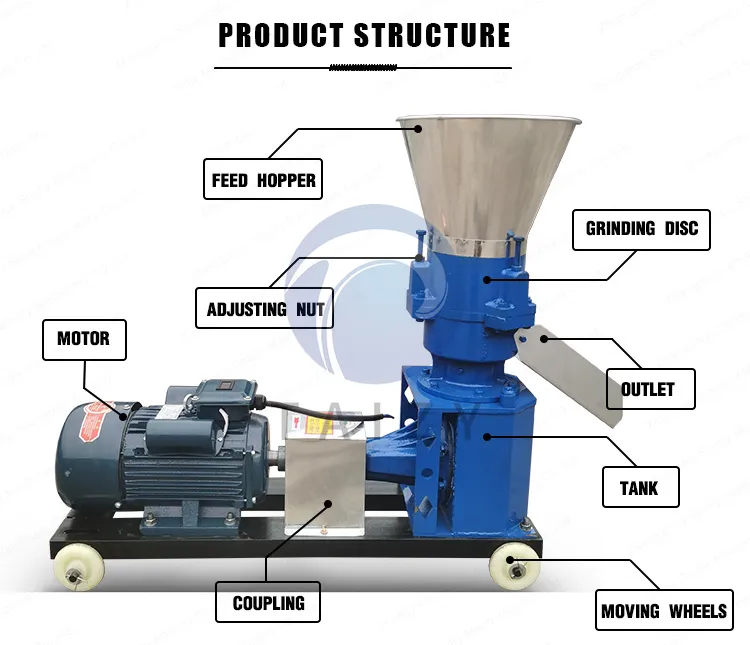

Poultry feed pellet making machine structure

The poultry feed machine mainly includes a feed hopper, adjusting nut, grinding disc, outlet, tank, motor, coupling, and moving wheels.

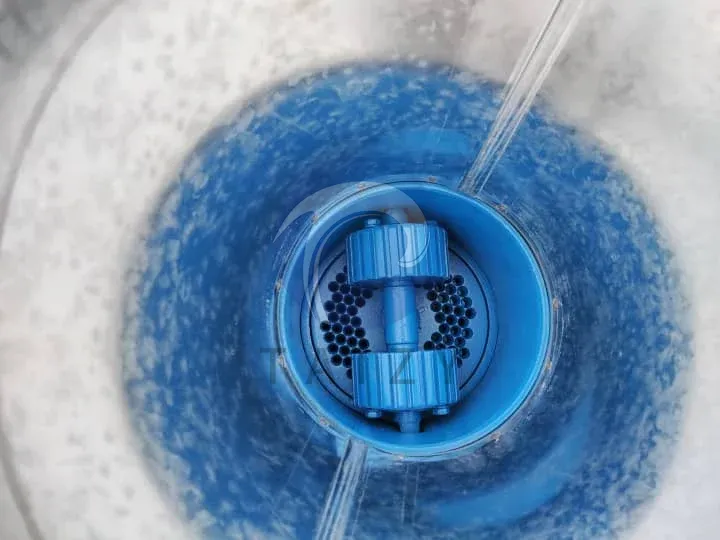

The main device inside the poultry feed pellet making machine is the roller, of which there are many types, such as the double-headed roller and the three-headed roller. But there are still other types of rollers that can be customized. If you want to know whether specific machine parts can be customized, please feel free to consult us!

In addition, we have different sizes of grinding discs to choose from. They have die holes in sizes from 2 mm-8 mm in diameter to suit feeding for different poultry.

The poultry feed pellet making machine has gained popularity among animal farmers and small-scale animal feed production lines due to its compact design, attractive appearance, high output, low power consumption, ease of use, and reliable performance.

Working principle of pellet making machine

The primary reason for producing feed pellets is that they provide a well-balanced mix of nutrients, promoting better growth for livestock, poultry, and other animals. The poultry feed pellet making machine is easy to operate. Before starting the machine, just mix the raw materials evenly. And then pour it into the machine.

The main components of this poultry feed pellet making machine include a flat, round steel die and a set of freely rotating grooved rollers. Raw material is poured into the hopper, where it then falls into the gap between the rollers from top to bottom. The rotating roller presses the material into the die hole, and finally, the long cylindrical object is extruded from the die hole and cut into particles by the cutter.

Generally, larger ingredients need to be ground down using a hammer mill. Additionally, protein or other nutrients can be incorporated into the raw material powder. Also, our machine can work with a chaff cutter and 9FQ. To save time in manpower, shaving and crushing grain.

Here is a detailed video of the process from YouTube.

If you’re unsure which option best meets your needs, please reach out to us directly. Our expert engineers will provide you with more detailed information for your consideration. Many of you might be particularly interested in the pricing. We are factory direct sales and can guarantee that you will get the most affordable price. If you have any questions, please get in touch with us right away!

Some tips and cautions for cattle feed pellet making machine

- Be careful not to allow foreign matter, such as stones and iron to enter the raw materials. After every ten shifts, the drum must be disassembled. Meanwhile, the high-temperature grease should be added to the bearings to ensure proper operation and extend its service life.

- During the pelletizing process, this press roller cannot contact the die plate or allow it to idle. You can tighten the press roller nut to prevent loosening and damage to the spindle keyway.

- If you find the pellets are broken or crushed, just reducing the crude fiber feed ratio to less than 50% will solve this problem.

- If pellets are not forming and no material is being discharged during the pelletizing process. These steps you can do at first: remove the die plate, drill each hole, add an appropriate amount of fiber feed, and restart the pelletizing process.

- Regularly checking the belt tension is a good way to maintain your animal feed pellet mill. If the gearbox is leaking, replace the oil seal promptly. Don’t forget to check the die head and press roller bearings for oil depletion periodically.

Global cases of Taizy feed pellet mill

1. Russian biomass pellet machine order

The client from Russia has his workshops, which mainly produce biomass fuel pellets. He tells us his ideal capacity of the machine, and the power he always uses to run it. Meanwhile, he asks if we have merchandise in stock, because he has a big order recently.

After we know his needs, we finalize the arrangements as soon as possible, including the model he wants, the power to meet his needs, and the way of shipping. The machine was put into operation immediately after arrival, with a significant improvement in performance and a doubling of production efficiency.

2. Burkifanaso poultry feed pellet making machine plant purchase

Our customer’s goal was to establish a local feed production facility to reduce dependence on imported feed and have lower production costs for improving overall livestock productivity. So he decides to order a fully automatic animal feed pellet mill plant.

After our recommendation and introduction, he finally chose Taizy production line. We arranged the cargo transportation immediately after the production line was completed and tested.

After the production line was installed and commissioned, our customer quickly began its full operation. He provides feedback that their feed costs have decreased by approximately 25%. And because the feed was highly palatable, some animals’ intake improved.

Fully automatic animal feed pellet press plant

This compact animal feed pellet mill line is suitable for both private and commercial applications. It includes a grinder, mixer, screw conveyor, silo, pellet mill, and cooler. If you’re considering starting an animal feed pellet manufacturing business, this is an excellent choice due to its low investment cost, minimal space requirements, and comprehensive features for producing animal feed pellets! (Read more: Animal Feed Pellet Milling Production Line>>)

If you are interested or would like to know its price and parameters, please do not hesitate to contact us directly! We provide you with equipment selection, plant layout design, cost estimation, and so on.