Our feed pellet production line is capable of producing 2-8 mm feed pellets with an output ranging from 800 to 1500 kg/h. This complete system is commonly utilized in small to medium-sized feed pellet production facilities, livestock farms, and by individuals who raise animals. The feed produced is suitable for a variety of animals, including pigs, cows, sheep, rabbits, chickens, ducks, geese, and other aquatic species.

An increasing number of farmers are opting to create their feed pellets to lower feeding costs, which is certainly a smart move. Additionally, this approach supports the advancement of modern animal husbandry, enhances the quality and efficiency of feed, and contributes to the health and productivity of the animals.

- Main equipment: feed pellet machine, mixer, and conveyor.

- Usage: producing feed pellets for various animals including chickens, ducks, fish, cows, sheep, horses, pigs, geese, pigeons, ostriches, camels, and more.

- Processable raw materials: corn, bran, straw, rice straw, alfalfa, oil meals (such as soybean, sunflower, and cottonseed), fish meal, corn meal, rice hulls, and others.

For detailed pricing, please share information about your raw material, animal, application, and any other relevant details. We will then provide you with tailored equipment options and the best pricing available!

Application scope of feed pellet production line

This feed pellet production line has a wide range of applications to meet the pellet production of different animals and production needs. The following is the main scope of the application:

- Poultry feed pellet production: feed production for chickens, ducks, turkeys, and other birds. Poultry of different ages and uses require different types of feed, and a variety of pellets can be produced to meet these needs.

- Livestock feed pellets: cattle, pigs, sheep, horses, and so on. These animals vary greatly in growth and usage and require specific types and sizes of feed.

Animal feed pellets with multiple advantages

Features of finished products include highly uniform pellet size, superior nutritional balance, ease of storage and delivery, reduced feed waste, and improved animal feeding efficiency.

- Maintaining high feed hygiene is crucial. The elevated temperatures during the chicken feed production process effectively eliminate common bacteria and fungi found in raw materials, including salmonella.

- On average, pellet feed has a capacity that is 15% greater than that of feed powder, preventing the separation of heavier particles like minerals and resulting in a more balanced feed.

- The nutritional value is enhanced through heat treatment and subsequent cooling during the pelletizing process, which boosts the feed’s digestibility and ultimately enhances livestock performance.

- Pellets are cleaner and produce less dust during transport compared to powdered feed. Additionally, they have a longer shelf life, which helps to minimize waste.

Workflow of animal feed pelletizing line

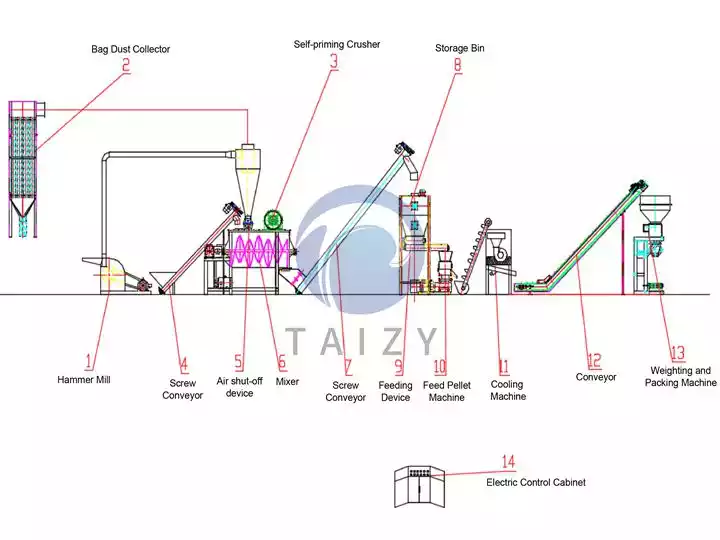

A complete feed pellet production line usually consists of a series of machines as follows: 9FQ Crusher → Mixer → Pellet Mill Machine → Cooler → Packaging Machine. These are the main core machines.

In addition, connecting the various machines before carrying out smooth work are lifting conveyor, bucket elevator, cache silo, dust remover, etc. As shown in the picture below:

Core machines introduction

9FQ-Crushing Machine

First, the raw material needs to go through a grinder to break into the proper particle size for subsequent feed pellet production line processing.

Mixer

The crushed ingredients enter the mixer and are blended well with other ingredients to ensure consistency and balanced nutrient distribution.

Pellets Making Machine

After mixing, the raw material enters the pellet mill and undergoes high pressure and molds to form pellets. These pellets can be adjusted to the desired size.

Cooling Machine

Ensure that finished pellets have the proper temperature, humidity, and quality to meet quality standards and improve the storage life of the feed.

Packaging Machine

Finally, the feed pellets are packaged through a packaging machine into appropriate package sizes for storage, transportation, and sale.

Pellet mill production line technical parameters

| NO. | Item | Specification |

| 1 | Material | Grains, Straw, Grass |

| 2 | Pellet Size | Diameter 2.5-8mm |

| 3 | Pellet Density | 0.6-1.2t/m3 |

| 4 | Capacity | 800-1500kg/h |

| 5 | Total Power | 89.16 |

| 6 | Covered area | 22*5*5 |

| 7 | Shipping | 40HQ |

We not only have motorized models of pellet mill machines but also produce diesel and tractor models. We support customization, welcome to consult us.

Taizy animal feed production plant benefits

- The feed pellet production line combines conveying, mixing, and granulation into a single unit, featuring a compact design, small footprint, minimal plant requirements, and low investment costs.

- There’s no need for on-site civil construction or welding; it can be used immediately after connection, resulting in low installation expenses.

- The system allows for continuous production, is easy to operate, and requires only 1-2 people to manage the entire production line, leading to reduced operational costs.

- It offers excellent transmission efficiency, smooth rotation, high output, and low noise levels, and prevents oil leakage and pollution, all while keeping component maintenance costs low.

- Additionally, it can be adjusted and customized to meet the specific needs of various animal species and their growth stages, ensuring the production of appropriate feed pellets.

For more detailed information about the feed pellet production line machine parameters and workflow, etc., we can help you with raw material evaluation pilot testing, etc. You are also welcome to visit our factory. In addition, please feel free to contact us to get a quotation.