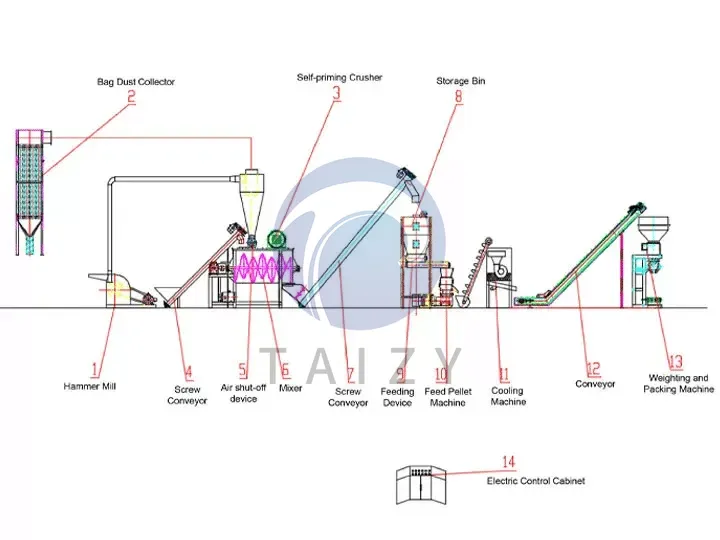

पूरी चीकन फीड उत्पादन लाइन में सामग्री क्रशिंग, मिक्सिंग, पेलेट बनाना और ठंडा करने के चरण शामिल हैं। यह पक्षियों, ब्रॉयलर, बत्तख आदि के लिए लगभग 1t/h की दर पर 3-8mm कण बना सकता है।

तैयार उत्पाद समान दानेदार रूप में होता है, जो पालतू जानवरों के पाचन और अवशोषण के लिए सुविधाजनक है। अभी तक, हमने इसे नाइजीरिया, इथियोपिया, बांग्लादेश आदि देशों को भी बिक्री किया है।

हमारे पास पेशेवर तकनीशियन हैं जो आपके कार्यस्थल और आपकी वास्तविक आवश्यकताओं के अनुसार सबसे उपयुक्त उत्पादन योजना डिजाइन करने में आपकी मदद कर सकते हैं। यदि आपको फैक्ट्री खोलनी हो या अपनी उत्पादन लाइन का विस्तार करना हो, कृपया हमसे संपर्क करें।

Taizy चिकन फीड उत्पादन लाइन कीHighlight

- Taizy की पूरी उत्पादन लाइन स्वचालित बैचिंग और तराजू प्रणाली से लैस है, जो सेट किए गए अनुपात के अनुसार स्वचालित रूप से सामग्री feed कर सकती है, मजदूरों की बचत और कार्यभार कम करती है।

- हमारी चिकन फीड उत्पादन लाइन अत्यंत स्वचालित है। वजन करने के बाद मशीन स्वचालित रूप से सामग्री बाहर छोड़ देती है और फिर अगले बैच के लिए वजन और बैचिंग शुरू कर देती है।

- हम कच्चे पदार्थों के पिसाई के लिए एक जल-ड्रॉप मिल का उपयोग करते हैं, जो उच्च पिसाई दक्षता और स्थिर संचालन प्रदान करता है, जिससे उत्पादन लाइन सुचारू रूप से चलती है।

- मिक्सर डबल-स्क्रू रिबन मिक्सर का उपयोग करता है, जिससे मिश्रण एक साथ uniform होता है ≥95%। यह सामग्री के समान वितरण और पेलेटिंग के दौरान गुणवत्ता को बनाए रखने को सुनिश्चित करता है।

- यह ऑटोमैटिक चिकन फीड उत्पादन लाइन कच्चे पदार्थ की विविधता के लिए अच्छी है और मक्का, गेहूं, दालें, तेल-बोयल भोजन आदि जैसे विभिन्न कच्चे पदार्थों को पेलेट करने के लिए उपयुक्त है।

हमारी चिकन फीड उत्पादन लाइन के कार्य चरण

कच्चे माल तैयार होने के बाद, आप उत्पादन लाइन को चालू कर सकते हैं। पीसने, मिलाने, पेलेटिंग और ठंडे करने के बाद, आपके पास अंतिम उत्पाद होंगे।

1.Grinding

साफ-सुथरे कच्चे पदार्थों को एक हथौड़ा मिल या क्रशर में डालकर महीन पाउडर में पीसा जाता है। (अशुद्ध कच्चे पदार्थों में पत्थर, कील आदि हो सकते हैं जो मशीन की आंतरिक संरचना को नुकसान पहुँचा सकते हैं और पेलेट निर्माण गुणवत्ता को प्रभावित कर सकते हैं।)

यह कदम कण आकार को छोटा करने के लिए किया जाता है ताकि मिलाने और पेलेटिंग बेहतर हो सके।

2. मिश्रण

कुचला गया पदार्थ फीड मिक्सर में डाला जाता है। अतिरिक्त जोड़, जैसे विटामिन, खनिज, अमीनो एसिड और अन्य पोषक तत्व, या तो मशीन में ही जोड़े जा सकते हैं। यह कदम फीड में पोषक तत्वों के समानDistribution सुनिश्चित करता है। (यदि जानवर बीमार हो तो दवाइयां भी जोड़ी जा सकती हैं।)

यही कारण है कि पेलेटेड फीड पारंपरिक कच्चे माल से अधिक लाभदायक है। मिलाने के माध्यम से पक्षी उन आवश्यक पोषक तत्वों को सीधे ग्रहण कर पाते हैं जो विकास के लिए आवश्यक हैं।

3. Pelletizing

मिश्रित फीड को पेलेट मशीन में डाला जाता है। उच्च तापमान और दबाव के अंतर्गत, फीड को कठोर, सम पेलेट में दबाया जाता है।

परिपक्व पेलेट न सिर्फ पचाने में आसान होते हैं और पोषण संतुलित होते हैं, बल्कि जानवर खाने पर कचरा कम करते हैं। स्टोर करने और परिवहन के लिए भी यह सुविधाजनक होते हैं।

4. Cooling

ताता पेलेट ताजा निर्मित होते हैं और गर्म तथा गीले होते हैं। इन्हें पेलेट कूलर के माध्यम से पास कराना होता है, जहाँ हवा का परिसंचरण तापमान और आर्द्रता को तेज़ी से कम कर देता है। यह कदम फफूंदी के विकास को रोकने और पेलेट की गुणवत्ता बनाए रखने में मदद करता है।

नोट: भंडारण या माध्यमिक फीड मिल्स में बाहरी बिक्री के लिए,/हम पैकेजिंग मशीनें भी प्रदान करते हैं, जो ठंडी पेलेट्स को स्वतः तौल कर बैग में डालती हैं (5 kg, 25 kg, या 50 kg उपलब्ध)।

बड़े पैमाने पर चिकन फीड उत्पादन लाइन में मुख्य मशीनें

हर कदम के लिए एक मशीन होती है। नीचे इसकी कार्य सिद्धांत और मॉडल पैरामीटर संक्षेप में बताए गए हैं।

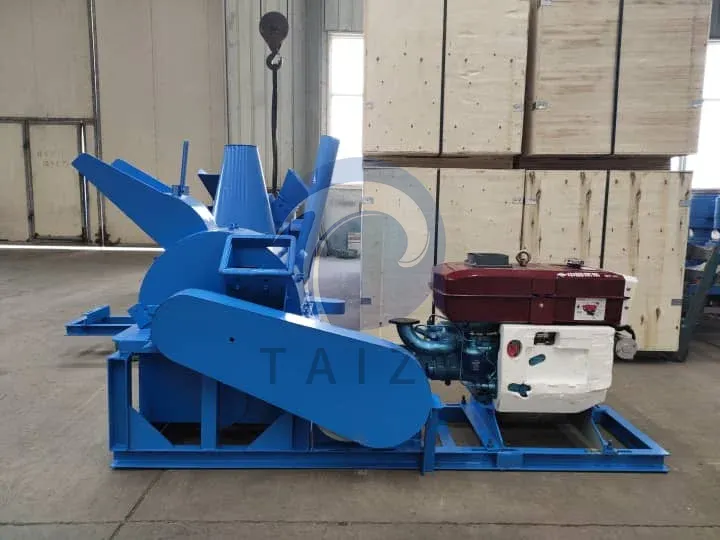

1. हैमर मिल

हथौड़ा मिल कच्चे पदार्थों को पाउडर में कुचल देता है ताकि अगले मिक्सिंग और फीड एक्सट्रूडर प्रक्रिया के लिए बेहतर हो सके। अलग स्क्रीन के mesh आकार बदलकर हथौड़ा मिल विभिन्न कण आकार के पाउडर उत्पादन कर सकता है।

| क्षमता | 600-1000kg/h |

| शक्ति | 18.5kw-22kw |

| आकार | 2000*1100*2300 mm |

| वज़न | 500kg |

2. Animal feed mixer

यह क्षैतिज मिक्सर पिसी हुई सामग्री को मिलाने के लिए उपयोग किया जाता है। यह पाउडर में सूक्ष्म पोषक तत्व, पोषण पाउडर आदि भी जोड़ सकता है जिसे हिलाने और मिलाने की आवश्यकता होती है। यह उपकरण मुख्य रूप से एक विद्युत मोटर को अपनी शक्ति के रूप में प्रयोग करता है।

| आयतन | 1.5सीबीएम |

| दीवार की मोटाई | 5 मिमी |

| रेड्यूसर शक्ति | 11KW/380V-50Hz |

| गति घुमाएँ | 18r/मिनट |

| निर्वहन तरीका | सिलेंडर खुला प्रपत्र |

| मशीन का आकार | 2100*1400*2000मिमी |

| बाल्टी का आकार | 1700*1200*1400मिमी |

| सामग्री | सामग्री के संपर्क में आने वाले हिस्से स्टेनलेस स्टील से बने होते हैं, बाकी हिस्से कार्बन स्टील से बने होते हैं। |

3. चिकन फूड पेलेट मशीन

पोल्ट्री फीड पेलेट बनाने वाली मशीन कच्चे पदार्थों को पीस कर सघन फीड पेलेट बनाती है। इसमें मक्का, अल्फाल्फा, ब्रान, और घास जैसे पदार्थों के 2mm, 4mm, 6mm, और 8mm जैसी सामान्य व्यास के साथ 80-700kg के पेलेट प्रति घंटे उत्पादन की व्यापक क्षमताएं हैं।

| नमूना | शक्ति | क्षमता | वज़न | आकार |

| TZ-120 | 3kw या 170F गैसोलीन इंजन | 80-100kg/घंटा | 75kg | 850*350*520मिमी |

| TZ-150 | 3kw या 170F गैसोलीन इंजन | 100-150किग्रा/घंटा | 81किग्रा | 850*350*570मिमी |

| TZ-210 | 7.5kw या 18HP डीजल इंजन | 200-300 किग्रा | 170 किग्रा | 990*430*710मिमी |

| TZ-230 | 11किलोवाट या 20HP डीजल इंजन | 300-450किग्रा/घंटा | 250किग्रा | 1000*450*960मिमी |

| TZ-260 | 15किलोवाट या 22HP डीजल इंजन | 400-500 किलोग्राम/घंटा | 290 किलोग्राम | 1300*450*1100 मिमी |

| TZ-300 | 22kw डीजल इंजन | 600-700किग्रा/घंटा | 397किग्रा | 1360*570*1150मिमी |

4. फीड कूलर

यह फीड पेलेट कूलर मशीन हमारी चिकन फीड उत्पादन लाइन में एक महत्वपूर्ण मशीन है, जिसका मुख्य कार्य उच्च तापमान पर प्रसंस्कृत कणों को त्वरित रूप से कमरे के तापमान तक ठंडा करना है और अप्रक्रिया पाउडर को अवशोषित करना है ताकि कुल उत्पादन क्षमता बेहतर हो सके।

| नमूना | शक्ति | उत्पादन | मशीन का आकार | वज़न |

| TZ-50 | 0.75+2.2kw | 0-500kg/h | 1800*750*1100mm | 220+65kg |

| TZ-70 | 0.75+2.2+2.2kw | 0-1000kg/h | 1800*750*1100mm | 220+120kg |

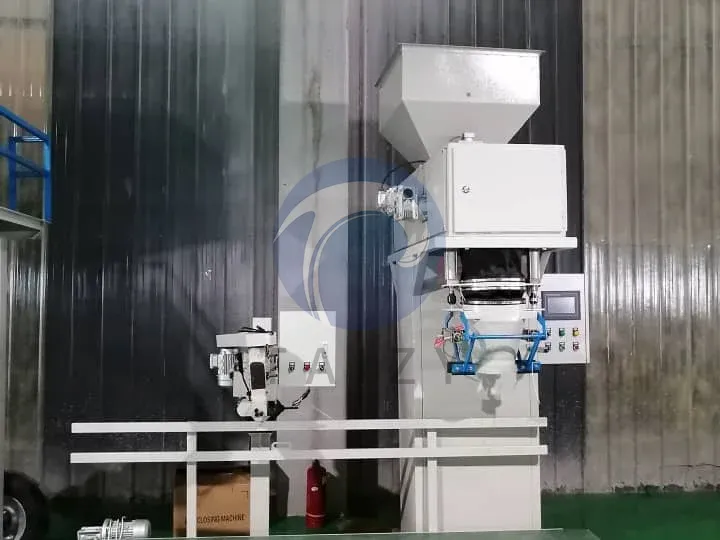

5. पेलेट पैकिंग मशीन

हमारी पैकिंग मशीन बड़े वजन वाले कणों को 10-50kg सही पैक कर सकती है, और यह वजन-नियमन प्रणाली से लैस होती है ताकि स्वतः मात्रा समायोजित और सटीक पैकिंग संभव हो सके।

| उत्पादन क्षमता | 15-60bags/min |

| मापने की रेंज | 10-50kg |

| बैग का आकार | L 80-360mm W 100-250mm |

| कुल शक्ति | 2.5kw |

| विद्युत आपूर्ति वोल्टेज | 220v,2.4kw |

| यंत्र का वजन | 550kg |

पोल्ट्री फीड उत्पादन लाइन के अनुप्रयोग

चिकन फीड उत्पादन लाइन एक बहुउपयोगी प्रणाली है जो पालतू पशुओं के पालन और फीड प्रसंस्करण उद्योगों में व्यापक रूप से प्रयोग की जाती है।

कुछ बड़े चिकन फार्म लागत नियंत्रण या अपनी फार्मिंग विधियों में नवाचार चाहकर छोटा फीड उत्पादन Línea खरीदते हैं। यह उत्पादन लाइन विभिन्न विकास चरणों और चिकन की नस्लों के लिए उपयुक्त फीड आवश्यकताओं को प्रदान कर सकती है।

व्यावसायिक फीड मिलें या कृषि सहकारी इसे उत्पादन लाइन का उपयोग करके बिक्री के लिए कस्टम फीड सूत्र बना सकती हैं। लाइन कई प्रकार के सूत्रों और सामग्री का समर्थन करती है, जो इसे बड़े पैमाने पर निरंतर उत्पादन (1-10 टन प्रति घंटा) के लिए उपयुक्त बनाती है ताकि उत्पादन आवश्यकताओं को पूरा किया जा सके।

यदि आप हमारी चिकन फीड उत्पादन लाइन में रुचि रखते हैं, कृपया हमसे संपर्क करें, और हम आपकी फैक्टरी के आकार और उत्पादन आवश्यकताओं के आधार पर एक मुफ्त उत्पादन लाइन इंस्टॉलेशन योजना प्रदान कर सकेंगे।