Last month, a Peruvian customer ordered a batch of feed pellet mill machines. He bought five fish pellet machines and ten animal feed pellet machines.

Customer profile

The client is in the breeding industry, and he breeds not only fish but also livestock. Faced with so much feed demand, he bought two types of feed pellet mill machines from us. According to the customer’s needs, we quickly determined the model of the machine he needed. We recommended him fish pellet machine and animal feed pellet machine. Combined with the customer’s local power equipment, he customized the electric motor and diesel fish pellet machine, and animal feed pellet machine.

animal-feed-pellet-machine

fish-food-pellet-machine

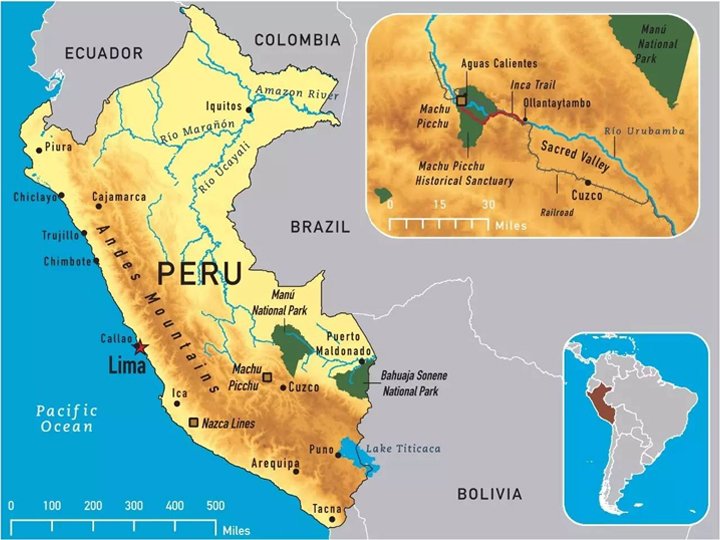

Overview of Peru’s fisheries

Peru has a long coastline of 2,254 kilometers. The coastal water temperature is suitable for fish reproduction. Fishery resources are very rich. It is one of the world’s largest fishing nations. According to the investigation, marine fishery and freshwater fish resources are very rich. Abundant fishery resources and a huge aquaculture market have driven the rapid development of the aquatic feed market. Our feed pellet machine can produce all kinds of aquatic feed, floating fish feed, grass carp feed, ornamental fish feed, tilapia feed, catfish feed, tongue sole compound feed, etc. The size of the feed is 1mm-12mm, which can meet the needs of different aquatic products.

Location-of-Peru

Aquaculture-in-Peru

The difference between fish pellet machine and animal feed pellet machine

Fish food pellet machine

Fish food pellet machine, mainly for aquaculture. Our fish pellet machine can produce floating fish feed and sinking fish feed, shrimp feed, catfish feed, other aquatic feeds, etc. It can not only produce feed pellets of different sizes but also feed pellets of different shapes. The Peruvian customer has customized 2mm, 4mm, and 6mm molds, including round, fish-shaped, and other shapes.

Animal feed pellet machine

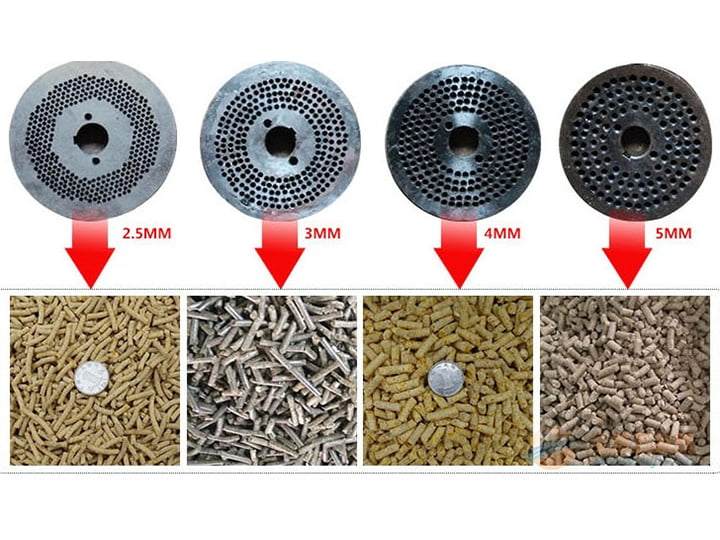

Animal feed pellet machine is feed pelletizing equipment. It is a feed processing machine, it can directly compress the pellets of crushed materials such as corn, soybean meal, straw, grass, and rice husk. The machine is mostly used in livestock breeding, such as cattle and sheep. According to your different needs, you can customize different molds to produce feed pellets of different sizes and lengths.

Advantages of feed pellet mill machines

Advantages of fish pellet machine

(1) The produced particles have low moisture content. And is easy to store. It can stay in its original state for a long time in the water, which greatly improves the utilization rate of the material.

(2) Surface of the feed pellet is smooth and the inside is matured, which can improve the digestion and absorption of nutrients.

(3) Floating pellet fish feed and sinking pellet fish feed can be produced according to different needs. Sink pellets are cheaper than floating pellets and can be used for pond fish farming. However, the floating pellet fish feed is not easy to cause waste, and it is also convenient for farmers to directly observe the feeding behavior of the fish and other conditions.

Advantages of animal feed pellet machine

(1) In the past, the feed was generally processed into powder and then fed. There are defects such as inconvenient feeding, poor palatability, picky eating by livestock, and low utilization rate, but the animal feed pellet machine can conveniently process powder feed into pellet feed. The pellets are extruded from the die hole under the squeeze of the pressing roller, and the length of the pellets can be easily adjusted.

(2) The machine has a simple structure, small floor space, and low noise.

(3) Adjust the feed formula in time according to the different growth periods of pigs, cattle, sheep, chickens, rabbits, etc., and the required nutrients.

(4) Machine structure is reasonable, firm, and durable.

Mould-of-fish-food-pellet-machine

Animal-feed-pellet-machine-mould

Operation specification of feed pellet mill machines

The feed pellet machine is the key equipment of various feed enterprises. Whether the pellet machine can operate normally or not, directly affects the economic benefits of the enterprise. Therefore, the correct operation of the pellet machine is important. Operators must be responsible for their work, and operate strictly in accordance with the operating specifications of the feed pellet machine. Startup and shutdown must be performed strictly in accordance with procedures.

Check before starting

- Whether there is any storage, agglomeration or debris in the feeder, granulation room, etc.

- The transmission part is operating normally or not.

- Whether the gap between the pressure roller, the pressure mold and the mold roller is normal.

- Whether the safety device works.

- Remove iron impurities from the iron separator.

- Idling test rotation, check whether the inner mold is rotating and the sound is normal.

Boot

- Turn on the main power supply and turn on the machine.

- After the granulator is running smoothly, the feeder supplies material.

- Re-adjust the working conditions according to the quality requirements until the best condition.

- Pay attention to the fluctuation of the granulator during normal production, and stop the machine for inspection if you find any abnormality.

Shutdown

- Reduce the amount of feed.

- When the material volume drops to zero, shut down the equipment.

- Turn off the main power supply of the pellet machine.

Finally, always check the wear of the vulnerable parts of the pellet machine to avoid sudden equipment failure.