Since self-prepared fish feed can make full use of agricultural and sideline products and reduce feed costs, as the price of feed commodities rises, many breeding farmers have begun to produce self-prepared fish feed. However, many breeding farmers lack the knowledge of fish nutrition and feed. There are many misunderstandings in the production of self-prepared fish feed. Such as some breeding farmers are pursuing high protein one-sidedly, and some are pursuing low-cost one-sidedly while ignoring the fish requirements for nutrition. The demand for nutrition has resulted in increased feed costs. To produce high-quality and efficient self-prepared fish feed, the following aspects must be considered.

Reasonably Design the Feed Formula

Before designing a fish feed formula, it is necessary to understand the type and growth stage of the farmed fish to determine the level of nutrients such as protein and energy in the feed. The fish feed formula must not only meet the needs of fish for protein growth but also make the ratio of energy and protein moderate. Both too high and too low energy-to-protein ratio is not conducive to fish growth.

When designing the fish feed formula, it is also necessary to consider the relationship between the nutrient water and the bulk density of the feed. It is also necessary to ensure that the fish can take insufficient nutrition and make it feel full. Fish mainly use protein as an energy source, and the utilization rate of fat and carbohydrates is low. Therefore, the protein demand of fish is higher than that of livestock and poultry. Different stages of fish growth have different requirements for various nutrients. For example, the protein content of carp juvenile feed is 43%-41%, small fish is 37%-42%, adult fish is 28%-32%.

Selection of Fish Feed Ingredients

When selecting feed ingredients, the principles of high quality and low price, stable supply, and convenient transportation should be followed. When conditions permit, the more types of raw materials, the better, so that the necessary amino acids in the feed can be balanced as much as possible.

To maximize the needs of fish for various essential amino acids. Moldy raw materials contain a lot of bacteria and toxins. For example, moldy corn contains highly toxic aflatoxins. These feeds are very easy to cause fish disease after being fed.

Although raw materials such as cottonseed meal and rapeseed meal are cheap and have high protein content, they contain anti-nutritional factors such as gossypol and glucosinolate respectively, and excessive feeding will affect the growth of fish.

So limit the amount, generally not more than 10%. Many farmers like to use cheap oil residue and meatloaf, but these raw materials are mixed with a large number of animal skins, which affects the smooth progress of the crushing and pelleting process, and the fish is not easy to digest after eating.

The fat contained in oil residue and meatloaf is saturated fat, and rancidity will occur if stored for a long time. Fish have a low utilization rate of saturated fat, and excessive intake of rancid fat can also cause fish to suffer from fatty liver and other diseases.

Therefore, the amount of such raw materials should be controlled below 5%. In addition, attention should be paid to the moisture content of the raw materials when selecting raw materials. Excessive moisture will reduce the nutritional value of the fish feed, and may also lead to mildew of the feed and shorten the storage time of the feed.

Control of Fish Feed Processing Technology

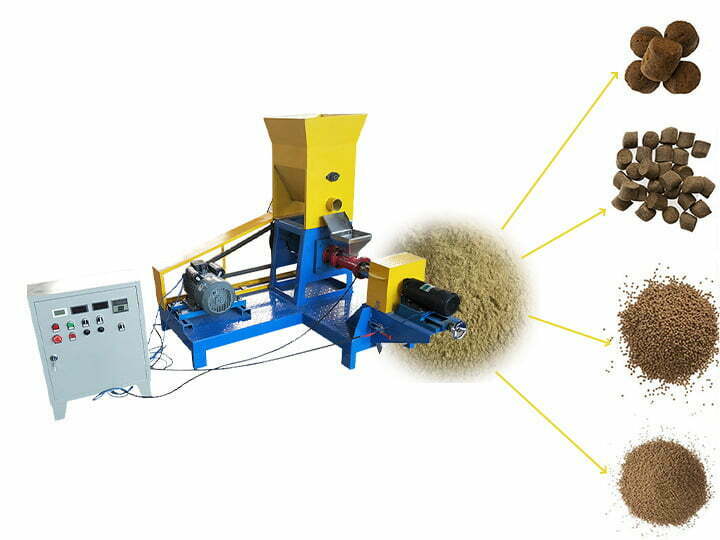

The process of producing self-prepared feed generally includes crushing, mixing, fish feed pellet machine, and conditioning. The machines used in the process include a grinder, mixer, fish feed pellet mill machine, or fish feed mill machine.

The raw materials crushed by the crusher machine can increase the contact area between the feed and animal digestive enzymes. It improves the digestion and absorption of substances, nitrogen, and energy, and reduces the feed coefficient. Too coarse or too fine crushing particle size is not good.

The optimal crushing particle size of carp fingerling feed is 177цm. The crushing particle size of carp juvenile compound feed is 0.30-0.25mm. Mixing is the main link to ensure the quality of the mixed feed and improve the feed effect.

Feeding practice shows that if the components in the raw feed are not uniformly mixed, it will affect the growth of fish. And in severe cases, it will lead to death. This is because the uneven mixing makes the distribution of various nutrients in the feed uneven. It can not achieve the effect of the formula, and the local concentration of certain additives such as heavy metals will cause fish poisoning and death.

The mixer we produce contains a mixing steel strip, which can fully mix various feed ingredients. So as to avoid the above problems. At the same time, this is also the advantage of machine-produced fish feed and artificial fish feed.

How to Process Fish Feed Through a Fish Feed Mill Machine?

Through the above control of the processing industry, we pour the crushed and stirred self-prepared feed into the fish feed extruder. Then adjust the production speed and shape by adjusting the machine. Through this fish feed extruder, you can produce floating fish feed or sinking fish feed.