Our pet food extruders use a thermal expansion method to compress and heat the raw materials into pellets. It can manufacture feed of different sizes and shapes for different pets (such as dogs, cats, fish, and birds).

This machine produces compact, highly palatable pellets with a variety of choice of pellet sizes (1-11mm) to suit the needs of pets at different growth stages. Its capacity has a wide range of 40-1200kg/h, suiting different pet food production companies of all sizes.

Advantages of the industrial pet food extruder machine

- Our machine produces uniform and aesthetically pleasing pellets, effectively ensuring product quality.

- When ordering the machine, we offer a variety of molds to choose from, which can produce pet food in various sizes.

- Except for feeding, all operations are fully automated, making it easy to operate and integrate into the production line to improve efficiency.

- Taizy machines have a long lifespan. We have professional after-sales service personnel to solve your subsequent maintenance and repair problems.

What is a dog food-making machine?

A pet food extruder is a machine specifically designed for producing extruded and cooked pet food under high temperature and pressure. It mixes, extrudes, and produces uniform pellets from powdered raw materials.

Unlike traditional pet food makers, this machine uses thermal expansion, which effectively kills most parasites and bacteria, ensuring food safety. The extruded pet food is a cooked product, offering better palatability and digestibility, making this machine an ideal choice for producing high-quality dog and cat food.

Working principle of the pet food extruder

Step 1: Raw material mixing. Basic ingredients typically include cornmeal, meat meal, and animal fat. Multivitamins and flavoring agents can also be added during mixing to enhance flavor and nutrition.

Step 2: Screw extrusion. The raw materials are sterilized and cooked under high temperature and pressure. The machine uses a screw extruder to form a dense, linear finished product.

Step 3: Shaping and cutting. Different molds are used to create shapes such as bones, fish, and spheres. Custom shapes are available upon request.

Step 4: For space-constrained applications, we also provide dryers and seasoning machines to improve taste and extend shelf life.

Models and technical parameters of the dog food machine

We have over a dozen different models to meet various production needs. Below are some of our best-selling styles.

Model 1: DGP-60

| Model | DGP-60 |

| Main motor power | 15kw |

| Feeding power | 0.4kw |

| Cutting power | 0.4kw |

| Production capacity | 120- 150kg/h |

| Overall dimensions | 1450*950*1430mm |

| Machine weight | 480kg |

Model 2: DGP-80

| Model | DGP-80 |

| Main motor power | 22kw |

| Feeding power | 0.4kw |

| Cutting power | 0.4kw |

| Production capacity | 300-350kg/h |

| Overall dimensions | 1850*1470*1500mm |

| Machine weight | 800kg |

Model 3: DGP-120

| Model | DGP-120 |

| Main motor power | 55kw |

| Feeding power | 2.2kw |

| Cutting power | 1.1kw |

| Production capacity | 600-700kg/h |

| Overall dimensions | 2200*2010*1700mm |

| Machine weight | 1850kg |

If you want to know other models’ parameters and details, please contact me to gain them. You can send me an email or consult on WhatsApp, and I will reply to you as soon as possible!

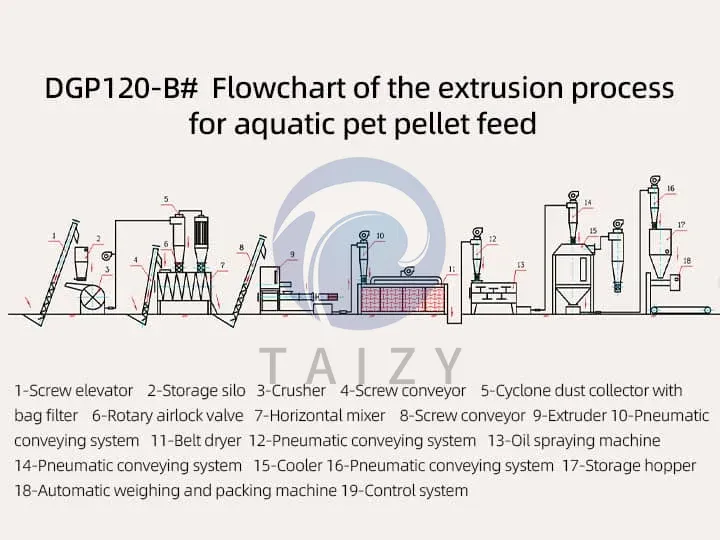

Complete pet food production line configuration

In addition to this pet food extruder, we also offer smaller production lines to meet the automation needs of different customers. A standard complete pet food production line includes: a feed grinder, mixer, extruder, dryer, flavoring machine, and packaging machine.

If you are unfamiliar with this, we can also provide a product list based on your budget for you to choose from. What’s more, our technicians will tailor the specific machine selection for your production line based on your production volume requirements and the actual area of your factory.

Customer case

We have one client who is a Moroccan agricultural processing company that previously focused on producing animal feed and seafood by-products. Based on his experience in feed formulation, he decided to expand into the pet food business to meet domestic demand.

After searching online for several suppliers, the client found Taizy through our website and videos showcasing pet food makers in operation on YouTube. He contacted us seeking a customized solution capable of processing dog and cat food at a capacity of approximately one ton per hour.

Our engineering team recommended the TZ-1000 Pet Food Extruder Production Line to meet his needs, which includes: a mixer, screw conveyors, a DGP-160 dry dog food machine, a dryer, a seasoning machine, and a packing machine.

After the machine was put into trial production, our customer immediately put it into production at their factory and gave us the following feedback.

“They run smoothly. I am satisfied with the whole line. We are proud to produce our own Moroccan pet food brand and supply the local market competitively!”

Contact us!

If you want to start your pet food business, and want to find a reliable manufacturer. Taizy is one of your most suitable choices! We have our factory that can not only provide you with a transparent price and good quality, but also ensure you the after-sales service.

When you have any problems or confusion about the machines, consult us to help you!