The floating fish feed pellet making machine is a feed processing machine that can directly handle the crushing of corn, soybean meal, straw, grass, rice husk or fish meal, and bone meal.

It can produce both sinking feed pellets and floating feed pellets, by changing a simple part of the machine, for underwater aquaculture fish, shrimp, and ornamental fish. Raw materials after high temperature and high-pressure processing are cooked feed. The machine output is up to 2t/h.

Usually, we can use the grain grinder to crush the materials. Also, we can use the seasoning machine to season the fish food.

Brief introduction of the floating fish feed pellet making machine

From 40kg per hour to 2 tons per hour, our fish feed pellet making machines have many models with different capacities to meet a variety of customers’ demands. It’s widely applicable to large, medium, and small aquaculture, individual farmers, and small and medium-sized aquaculture use.

Furthermore, we provide two kinds of engine, electric motor, and diesel engine, which is a great option for some remote areas lacking electricity. In recent years, it’s been widely welcomed by customers from America, Congo, Nigeria, Togo, Myanmar, Vietnam, Brazil, Peru, Ghana, Niger, etc.

How does the fish feed machine work?

What is the working principle of a fish feed machine?

Firstly, put the material into the feeder. Then the material will enter the extrusion screw and then into the compression chamber.

The materials will through the first stage of the steam plug to get the initial extrusion and heating.

After that, it is continuously heated by different degrees of extrusion until the material is discharged.

Technical parameter of fish feed pellet machine

| Model | Capacity (t/h) | Main Engine Power (kW) | Feeding Power (kW) | Screw Diameter (mm) | Cutting Power (kW) |

| DGP40 | 0.04-0.05 | 5.5-7.5kw12HP diesel engine | 0.4 | Φ40 | 0.4 |

| DGP50 | 0.06-0.08 | 11 | 0.4 | 50 | 0.4 |

| DGP60-B | 0.10-0.12 | 15 | 0.4 | Φ60 | 0.4 |

| DGP70-B | 0.18-0.20 | 18.5 | 0.4 | φ70 | 0.4 |

| DGP80-B | 0.25-0.30 | 22/27 | 0.4 | φ80 | 0.55 |

| DGP90-B | 0.40 | 30 | 0.75 | Φ90 | 1.5 |

| DGP100-B | 0.50 | 37 | 0.75 | Φ100 | 1.5 |

| DGP120-B | 0.60-0.70 | 55 | 1.1 | Φ120 | 1.5 |

| DGP135-B | 0.75-0.80 | 75 | 0.75 | φ133 | 1.5 |

| DGP160 | 1.0-1.2 | 90 | 1.5 | Φ160 | 2.2 |

| DGP200 | 1.8-2.0 | 132 | 2.2 | Φ200 | 2.2 |

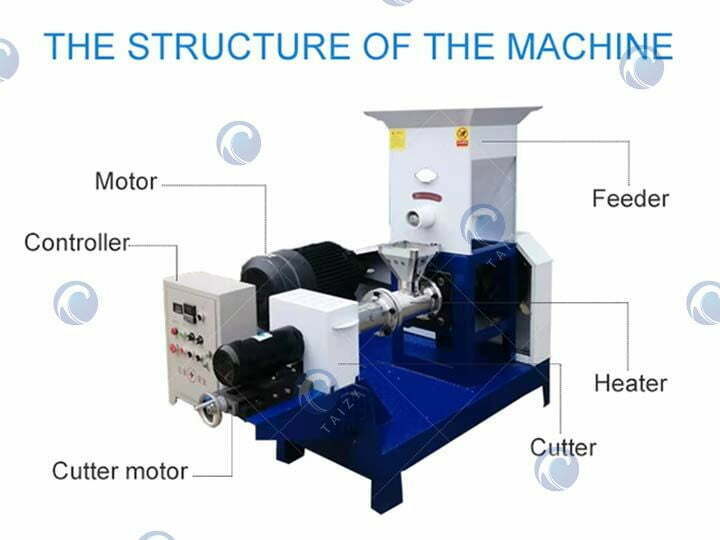

Main structure and functions of floating fish feed machine

This floating fish feed machine is mainly composed of a feeder (bucket), extrusion unit, power, drive system, frame, electronic control system, etc. Fish feed pellet making machines occupy a small area and are easy to operate.

Function of each part of the fish feed pellet making machine

- Feeder. The feeder is a speed-adjusting screw, which is composed of a hopper, conveying screw, discharging pipe, shell, and decelerating motor.

- Extrusion unit. The extrusion unit is the core part of the feed pellet machine, according to different raw materials, and different ways of discharging to choose a suitable model and group.

- Electric control system. According to the power size of the host and feeding form, the configuration is also different. This fish feed pellet making machine has an independent control box that is fixed to the machine. Each motor of this system can start and stop independently.

What advantages does the fish feed pelletizer have?

- This fish feed machine can adapt to different production requirements. Medium and large feed mills can use this machine for raw material processing or special feed production. For example, detoxification of expanded whole fat soybean, expanded corn, cotton meal (or vegetable meal) pet feed, fish feed, or other special feed. Small feed mills or large and medium-sized farms can also use the puffing machine as the main equipment to produce full-price puffing feed.

- The fish feed pellet making machine can adapt to different materials and different production conditions. Our machine is equipped with speed governing feeder, the output can vary according to the situation and customers’ demands.

- The extruding screw is a combination structure of sleeve type, and the screw sleeve is a steel bar type structure with an inner cylinder. According to different swelling requirements, the extruding screw group can be flexibly composed and then matched with different materials, which can adapt to different processing conditions.

- The structure of the machine is simple and practical. The machine is compact in shape, simple in structure, and easy for users to operate and maintain.

- Multiple power engines are adaptable. We have a deep understanding of the power shortage in some African regions and some remote areas. So our machines can be used not only with electric motors but also with diesel engines.

- The fish feed pellet making machine can output both floating feed and sinking feed. It can easily adjusted by changing a spare part.

Simple production line of floating fish feed extruder

Since 2018, we have found that many customers at home and abroad need a simple production line. This production line includes a crusher, mixer, screw conveyor, and fish feed pellet machine. Hammermill machine is a good choice for a crusher, it crushes raw materials into powder or tiny particles. A stainless steel mixer mixes the various powders of the ingredients well. The screw conveyor lifts and transfers the material into the feed pellet machine automatically. Then the pelletizer produces the final production.

The whole fish feed pellet making machine line is simple and cheap but can save human labor to a great extent, which meets many customers’ requirements. We will recommend the most suitable model of each machine to you according to the plant area and your budget.

Successful case

In the summer of this year, a customer from Burma sent us an inquiry about a fish feed pellet making machine. He had cooperated with Burma’s local government purchasing section and needed to order 50 sets of fish feed pellet machines.

We sent him detailed technical parameters of each model to figure out which suits local situation requirements best. After consideration and negotiation for about 3 weeks, the customer got the approval and allocation from the local government.

He placed the order for 50 sets of fish floating pellet machines and asked us to print 50 pcs of paper manual book. We accepted his requirement and delivered the item in August. After receiving our machines in September, he told us the local government was very satisfied with our machines and would like to order more in the next year.

FAQ

What kind of engine does this machine use?

Electric motors and diesel engines are both suitable.

What’s the material of this fish feed pellet making machine?

Most of it is made of carbon steel, the screw is stainless steel.

What’s the capacity of this machine?

From 40kg per hour to 2 tons per hour, we have many different models. Please check the parameter form in the article.

Can I change the shape of the final pellet?

Yes, of course, we will provide 6 different molds for free if you buy our machine. Also, we accept customization, you can send us the shape you want and we will produce the molds.

What are the spare parts?

Screw, screw sleeve, and mold.

What kind of payment terms do you provide?

Trade Assurance, T/T, Western Union, Money Gram, L/C, Pay Pal, Cash, etc..

How long is the warranty time?

1-year warranty time, life-long maintenance.