Taizy floating fish feed pellet making machine mixes and processes raw materials into fish feed pellets. Its production capacity ranges from 40 to 2,000 kg/h, which makes it suitable for fish feed factories and fish farms of various scales. The same machine, combined with different molds, can produce fish feed of many sizes, suitable for carp, catfish, and tilapia farming.

The fish feed pellets processed by Taizy floating fish feed extruder machine have high hardness, smooth surface, and internal maturation, which can improve the digestion and absorption of nutrients. The high-density pellets are moisture-resistant, making them easier to store and transport.

Brief introduction of fish feed pellet making machine

Taizy floating fish feed pellet making machine is a single screw extrusion type of extruding equipment, which can process various aquatic feeds. Besides, it can process not only a single raw material but also a variety of materials. Note: before processing the material, we should use the feed mixer to mix it well.

The pellet formation process can denature the pancreatic enzyme resistance factor in cereals and legumes to reduce the adverse effects on digestion. It also reduces all kinds of worm and digestive system diseases. Use our machine to create your exclusive feed recipe for healthier fish growth.

Our fish food production machine features low noise, high work efficiency, convenient operation, and comprehensive functions. Furthermore, we offer a range of fish food manufacturing machine models to meet varying capacity requirements. Customers can choose the model that best meets their specific production needs.

Additionally, we offer a range of molds suitable for various fish species. Each mold can be used to produce feed pellets of different sizes. It is used to adapt to different stages of fish and the feeding preferences of different types of fish.

Advantages of the fish feed pellet manufacturing machine

- This fish feed pellet machine can adapt to various production needs. It can be used for specialized feed production in the large feed mill industries with high production volume. Fish farms also use it as the primary equipment to produce feed that meets the needs of fish at different growth stages.

- This floating fish feed pellet machine can be adjusted to suit different materials and production conditions. It can produce both floating and sinking feeds, making it extremely versatile.

- Taizy fish feed pellet extruder machine has a simple structure, and it is practical. The whole machine is exquisite in shape, simple in structure, and easy to operate and maintain.

- Our floating fish feed pellet making machine features low energy consumption and high maneuverability.

- This fish food pellet machine has wide applicability, a small footprint, and low noise.

- The fish pellet feed produced by the floating fish feed pellet machine can effectively prevent and control fish diseases.

- Taizy floating fish feed extruder is equipped with various aperture molds. They are suitable for the granulation of different materials and can achieve the best effect.

If you don’t know which one is more suitable for your fish farming business or industrial fish feed pellets industry, you can consult us. Taizy service staff will provide you with free machine purchase suggestions based on your production requirements and main raw materials.

Using scope of floating fish feed pellet making machine

The fish feed extruder machine can produce feed suitable for fish, shrimp, dogs, cats, etc. The raw materials can include cereals, meat, flour, soybean meal, rapeseed meal, and cotton meal, among others.

It is widely used in large, medium, and small aquaculture, such as fish farming in ponds, fish farming in paddy fields, fish farming in tap water, cage farming, and captive fish farming in seawater.

Besides making fish feed pellets, this floating fish feed pellet-making machine has a wide range of applications for producing dog food pellets, cat food pellets, bird food pellets, etc..

More than a dozen kinds of molds can be selected to produce feed pellets of different shapes and sizes. The expansion of the raw material through thermal expansion makes the product easier to digest and assimilate.

We also offer a seasoning machine for adding attractants, vitamins, and minerals.

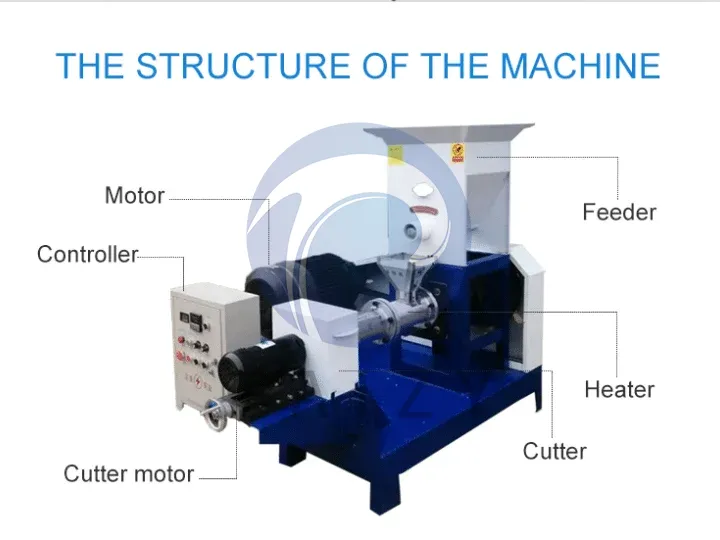

Structure of floating fish food manufacturing machine

The structure of the feed pellet machine mainly includes a feeder (bucket), extrusion device, power and transmission system, frame, electric control system, etc.

- The feeder (hopper) is of an automatic speed regulation type. And it consists of a hopper, a pushing screw, a discharge pipe, and a shell.

- The extrusion device is the core part of the fish feed pellet machine. According to different uses, that is, extruding different materials and different discharging methods, we can select the corresponding combination.

- The floating fish feed pellet making machine has an independent control box, which can be placed on one side of the machine or fixed on the frame. Its power source can be an electric motor or a diesel engine.

Working principle of fish feed pelletizer

Let’s take dry puffing as an example to show how this machine works:

- The material is propelled from the feed box into the compression chamber by the extrusion screw (or screws), where it undergoes initial extrusion and heating.

- It then continues to undergo a variety of degrees of extrusion and heating until discharge.

- The extruded feed creates long, uniformly thick strands, which are then sliced into preset sizes by a rapidly rotating cutter.

To achieve different discharge effects, the gap between the screw plug and the bullet head can be adjusted, and the template with different discharge hole diameters can also be replaced.

The discharge hole diameter series is φ1mm, φ1.5mm, φ2mm, φ3mm, φ3.5mm, φ4mm, φ5mm, and φ6.8mm. You can choose the right size of molds you need.

Parameters of small fish food manufacturing machine

There are 6 types of fish feed pellet mills, which have different capacities, screw diameters, and power choices.

| Model | DGP-45 |

| Capacity | 40-50kg/h |

| Main power | 7.5kw |

| Cutter power | 0.4kw |

| Feed supply power | 0.4kw |

| Screw diameter | 40mm |

| Size | 1260*860*1250mm |

| Weight | 290kg |

| Model | DGP-60 |

| Capacity | 120- 150kg/h |

| Main power | 15kw |

| Cutter power | 0.4kw |

| Feed supply power | 0.4kw |

| Screw diameter | 60mm |

| Size | 1450*950*1430mm |

| Weight | 480kg |

| Model | DGP-70 |

| Capacity | 180-250kg/h |

| Main power | 18.5kw |

| Cutter power | 0.4kw |

| Feed supply power | 0.4kw |

| Screw diameter | 70mm |

| Size | 1600*1400*1450mm |

| Weight | 600kg |

| Model | DGP-80 |

| Capacity | 300-350kg/h |

| Main power | 122kw |

| Cutter power | 0.4kw |

| Feed supply power | 0.4kw |

| Screw diameter | 80mm |

| Size | 1850*1470*1500mm |

| Weight | 800kg |

| Model | DGP-100 |

| Capacity | 500-550kg/h |

| Main power | 18.537kw |

| Cutter power | 1.1kw |

| Feed supply power | 1.5kw |

| Screw diameter | 100mm |

| Size | 2000*1600*1600mm |

| Weight | 1500kg |

| Model | DGP-120 |

| Capacity | 600-700kg/h |

| Main power | 55kw |

| Cutter power | 1.1kw |

| Feed supply power | 2.2kw |

| Screw diameter | 120mm |

| Size | 2200*2010*1700mm |

| Weight | 1850kg |

| Model | DGP-135 |

| Capacity | 750-800kg/h |

| Main power | 75kw |

| Cutter power | 1.5kw |

| Feed supply power | 0.75kw |

| Screw diameter | 133mm |

| Size | 2300*2150*1800mm |

| Weight | 800kg |

| Model | DGP-160 |

| Capacity | 1000-1200kg/h |

| Main power | 90kw |

| Cutter power | 2.2kw |

| Feed supply power | 1.5kw |

| Screw diameter | 160mm |

| Size | 3050*1950*1750mm |

| Weight | 3600kg |

| Model | DGP-200 |

| Capacity | 1800-2000kg/h |

| Main power | 132kw |

| Cutter power | 2.2kw |

| Feed supply power | 2.2kw |

| Screw diameter | 200mm |

| Size | / |

| Weight | / |

Note: All the machines have two types of power: the electric motor and the diesel engine. You can choose it according to your needs. If you don’t know how to choose the right one for your requirements, don’t hesitate to contact us. We have a professional service for helping you solve such problems.

Why use a floating fish feed pellet making machine?

- Pellet-feed fish farming has less pollution to water quality, which is convenient for water quality management. Our fish pellet mills produce pellets with high density, which makes fish easier to consume.

- Floating pellets remain on the water surface for hours without disintegrating, so fish will have more time to eat, which minimizes overfeeding.

- Pellets stay in the water for a short time and lose fewer nutrients, which is beneficial to the digestion and absorption of fish. Therefore, the utilization rate of feed is improved, and the feed coefficient is reduced.

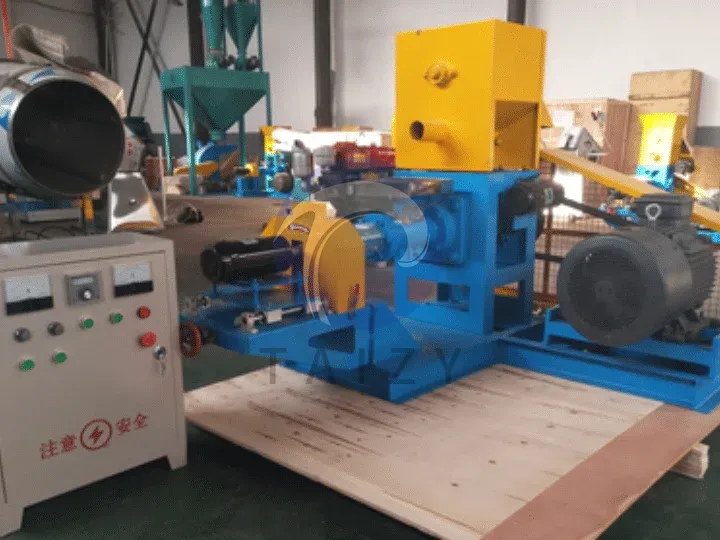

Successful case of fish feed pellet mill

Customers from Belgium leave their contact details by browsing our floating fish feed pellet making machine website. So, our sales managers communicate with customers via WhatsApp.

In the process of communication, we learned that the customer needs a fish food pellet machine with an output of 40kg per hour. And the power of the machine is a diesel engine to add to his small fish feed production facility.

After fully understanding his needs, we recommended the DGP-45 feed pelleting machine, which perfectly met his requirements in terms of power and output.

Since our factory had already finished the product, we shipped it directly. Below is an image of the machine’s packaging and shipping.

Our feed pelleting machine has been used by feed mills and fish farms worldwide, including in Nigeria, Malaysia, Peru, and Ghana. If you share the same needs and are looking to upgrade your machine or expand production, please don’t hesitate to contact us.

Contact us at any time

Our factory has been focusing on manufacturing pellet-making machines for many years. In addition to machines for processing fish food pellets, we also produce poultry feed pellet machines. If you are interested, please click Pellet Mill Animal Poultry Feed Pellets Making Machine.

We sincerely invite all customers who are interested in floating fish feed pellet making machines to consult us at any time. Whether it is product information or technical support, we are happy to answer you.

At the same time, we warmly welcome you to visit our factory. We look forward to establishing a long-term cooperative relationship with you and jointly promoting the development of the aquaculture industry!