Extruder is a machine processing and producing puffed food. Corn, rice, wheat, rice and other grains that are common in our daily life can be processed into puffed food by extruder. The way it works is that the heat generated by the machine creates a high temperature and high pressure environment. Then the extruder squeezes the raw material to cooked food. This is the machine that makes the dry, crunchy snacks that are so common in our lives.

In recent years, with the rise and rapid development of food processing industry, extruder has been widely used in animal feed, pet food and other processing industries. Our pet food production line adopts twin screw extruder. Compared with single screw extruder, twin screw extruder is more suitable for producing feed pellet, when single one is more suitable for pasta and rice noodles. As the main machine of the pet food production line, the output of the extruder basically determines the output of the whole production line. All in all, this article will introduce 4 models of our most hot-sale extruder, and presents the details of twin screw extruder.

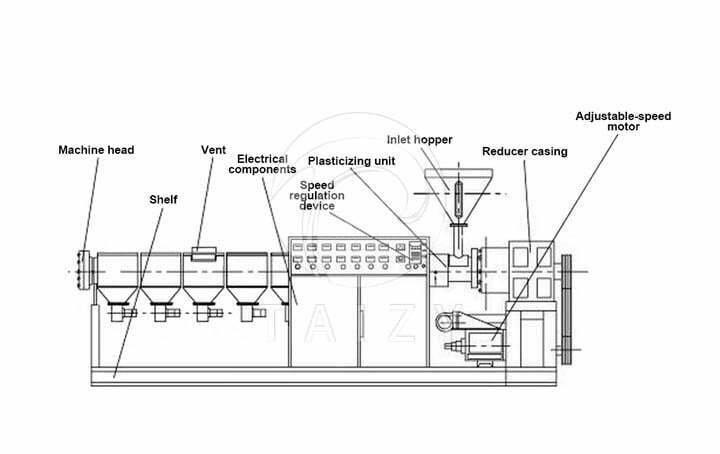

Structure and working principle description

The twin screw extruder mainly consists of machine head, shelf, vent, electrical components, speed regulation device, plasticizing unit, inlet hopper, reducer casing, and adjustable-speed motor.

First, the two screws are meshing with each other, and one screw is threaded into the screw groove of the other screw to form a extrusion chamber. Driven by the rotation of the screw, the material is forced out from the chamber. Then there comes the pellets. In addition, the shape and figure of the final pellets are changeable by changing different molds.

Technical parameter

| Model | DL65-III | DL65-II | DL70-II | DL80-II |

| Input Voltage | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ |

| Installed Capacity | 35KW | 46KW | 46KW | 90KW |

| Power Consumption | 22KW | 30KW | 30 KW | 55KW |

| Output | 100-150Kg/h | 150-200Kg/h | 200–260Kg/h | 300–500Kg/h |

| Size | 2.5×0.8×1.8m | 3.2×1.0×1.7m | 3.6×1.0×2m | 4.5×1.2×2.3m |

| Stainless steel thickness | 1.2mm | 1.2mm | 1.2mm | 1.2mm |

| Screws Material | 38CrMoAL/38 | 38CrMoAL/38 | 38CrMoAL/38 | 38CrMoAL/38 |

| Screw Length | 1050mm | 1520mm | 1520mm | 1563mm |

| Screw Diameter | 65mm | 65mm | 70mm | 80mm |

| Motor Power | 22kw | 30kw | 30kw | 55kw |

| Heating Power | 2kw*5 10kw | 2kw*5 10kw | 2kw*6 12kw | 3kw*6 18 kw |

| Feeding Power | 0.75kw | 0.75 kw | 0.75kw | 1.5kw |

| Cutting power | 0.75kw | 0.75 kw | 0.75kw | 1.5kw |

| Oil pump power | 0.37kw | 0.37kw | 0.37kw | 0.37 kw |

Raw material and final product

raw material

final product

Main function of twin screw extruder

- Dewatering. During the extruding process of general food or feed, the water content of pellet will lose 4-7% on the original basis.

- Condensation. During the expansion process, the raw materials are tightly combined into discrete pellets under the extruding action of the twin screw.

- Expansion. The operating conditions and configuration of the extruder control the density of pet food and aquatic feed (such as sinking or floating fish feed).

- Degassing. The bubbles of raw material are removed during the expansion process.

- Gelatinization. Under the extruding process, the machine can gelatinize starch (from various sources, such as tubers or grains) during the processing of food or pet feed.

Main features

- The main parts of the machine are made of special alloy steel by heat treatment, which has long service life, low maintenance cost and low feed production cost.

- Wet and dry processing are both available. Dry process adopts self-heating method, doesn’t need steam system. At the same time, the conditioning apparatus and the boiler can also be added for wet processing to make the extruded pellets smooth and delicate.

- The independent cutting device is connected with the machine body easily and quickly. Variable speed cutting head, can easily adjust the clearance between the cutting knife and the template. According to the required diameter and length, it can adjust the production of different specifications and shapes of final pellets.

- Screw design has a powerful self-cleaning function, screw and screw slot can be self-purification. So there’ s no need to stop cleaning if the user change the raw materials.

- No adhesive is needed to process the floating feed, which can maintain stability in water for more than 2 hours.

- The machine has novel design, compact structure and high production efficiency. And it is durable, low failure rate, easy operation and maintenance.

- Easy to use, with smooth transmission and low noise.

Successful case

In July this year, a customer from Venezuela sent inquiry to us about extruder. He was the purchasing agent of his company and needed to purchase a pet food production line. Besides, their procurement objectives were very clear, and they needed to customize the shape of several molds. Because of our professional and timely reply to his questions, we built mutual trust relationship quickly. After 3 weeks of negotiation, he placed the order of a complete pet food manufacturing plant. The plant included crusher, mixer, conveyors, extruder, oven, flavoring line, cooling machine and packaging machine. Later, he received the item in September and there was no problem of the machines. Then we provided a recipe of dog food to his reference. The customer was satisfied with our service and speed of delivery.

FAQ

1.What’s the material of the extruder machine?

The sheating material uses 201 stainless steel, the screw is alloy steel (38CrMoAL).

2.What’s the spare part of this machine?

Screw and mold.

3.Can I know the recipe of dog food (or cat food, birdseed, fish feed)?

Yes, but we only provide the recipe after you buy our machine.

4.What can be the raw material of this machine?

Grains and meat meal.

5.What’s the engine power of this machine? Does it need a air compressor?

It needs electric motor as engine power, it doesn’t need air compressor.

6.Can I change the shape of final product?

Yes of course. We can provide different molds with different shape holes according to your demands, we also accept customization.

7.How long is the warranty time?

1 year.

8.How will you deliver the item?

FCL or LCL by sea.